wolfseal KB 16, without upstand, waterproof up to a pressure head of 20 metres!

Application field

Basements, water containers and artificial concrete waterways regularly have joints. They are the result of different concrete sections and are not waterproof if they are not additionally sealed.

Basements, water containers and artificial concrete waterways regularly have joints. They are the result of different concrete sections and are not waterproof if they are not additionally sealed.Even if the building is completely covered with bituminous sheeting on the outside, we still recommend using the wolfseal joint system for all construction joints as an additional safety measure, because they will be washed-out by water even with minor damage. Without additional protection, water would get into the building.

This German working method is indeed special worldwide. Waterproof concrete basements – called “white tanks“ in Germany – are built by selecting special concrete types as well as with controlled concrete work at the construction site.

The concrete hereby not only assumes the static function but is simultaneously already fully water-impermeable without additional measures on the outside. High concrete quality is essential with this construction method and it must also be ensured that the concrete does not have any cracks. According reinforcement as well as different concrete technology measures hereby ensure reliable results.

Please refer to the section “Waterproof concrete basement“ for more information

Please refer to the section “Waterproof concrete basement“ for more informationSince construction joints in waterproof concrete basements are subject to direct water pressure without additional protection, most specialist engineers in Germany rely on the wolfseal joint system.

wolfseal joints systems are installed quickly and easily and are sealed up to a water pressure with a minimum pressure head of 20 m. Tested in the German material testing institute in Leipzig (www.mfpa-leipzig.de).

The product

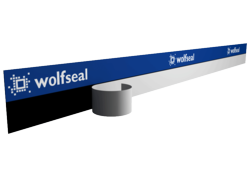

wolfseal KB 16 is made with hot-dip galvanised sheet steel with a height of 16.7 cm. The two-sided all-over wolfseal special coating bonds waterproof with the bordering concrete if this is connected with the wolfseal joint system before it hardens.

wolfseal KB 16 is made with hot-dip galvanised sheet steel with a height of 16.7 cm. The two-sided all-over wolfseal special coating bonds waterproof with the bordering concrete if this is connected with the wolfseal joint system before it hardens. A divided silicone paper reliably protects the wolfseal elements on both sides before they are glued together and also against contamination prior to concreting.

A divided silicone paper reliably protects the wolfseal elements on both sides before they are glued together and also against contamination prior to concreting. wolfseal elements are each 2 m long and safely packed in wooden crates in 100 m units. This not only ensures safe keeping of opened crates but also protects the freight against damage during shipment of the goods.

wolfseal elements are each 2 m long and safely packed in wooden crates in 100 m units. This not only ensures safe keeping of opened crates but also protects the freight against damage during shipment of the goods.

wolfseal KB 8 is available for the use in the wall/ceiling area; the product range also includes many accessories such as e.g. retainers, bar spacers or pipe ducts.

The processing

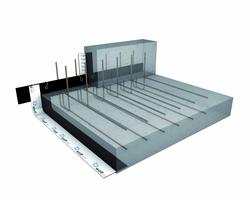

wolfseal KB elements are reinforced with retainers on the upper reinforcement where wall and floor meet horizontally.

The bottom protection paper is removed, the ends of top protection paper are folded back approx. 10 cm on one side. The individual elements are each overlapped by approx. 7 cm and firmly pressed together manually.

Each joint is additionally secured with a spring steel clamp.

F I N I S H E D !

The bottom protection paper is removed, the ends of top protection paper are folded back approx. 10 cm on one side. The individual elements are each overlapped by approx. 7 cm and firmly pressed together manually.

Each joint is additionally secured with a spring steel clamp.

F I N I S H E D !

Because the wolfseal joint system can withstand a pressure head of at least with an anchoring depth of only 3 cm, an upstand of the floor slab where wall and floor meet is no longer necessary.

All intersection points with vertical construction joints are simply connected at right angles and secured with cross clips.

In vertical wall joints, wolfseal KB is half boarded with wood in the first concreting section.

All intersection points with vertical construction joints are simply connected at right angles and secured with cross clips.

In vertical wall joints, wolfseal KB is half boarded with wood in the first concreting section.

Convincing advantages

- No welding of elements at the construction site

- No upstand required where wall and floor meet

- Watertight connection to wet concrete (2 bar with 3 cm anchoring depth in the concrete)

- Stability; no tilting to the side because of the reinforcement during concreting of the wall

- Less technical staff needed

- Connection to all expansion joint tapes possible